- Double Ferrule Type Tube Fitting

- I-fit (Single-ferrule Fitting)

- Fitting for Plastic Tubes

- Fitting for Vinyl Hoses

- Weld-less Fitting

- Automatic Welding Fitting

- Metal Gasket Seal FittingO-ring Seal Fitting

- Metal Gasket Seal FittingClamp type

- Quick Joint

- FF Quick Joints (Full-flow quick fitting)

- Bite Type Tube Fitting

- ISO-compliant Bite Type Tube Fitting

- High-pressure ThreadedSocket-weld Fitting

- Swivel Joint

- Hose Adapter

- Bunki-kunBranch header piping

- In-line Filter

- On-Site Flange (Weld-less Flange)

-

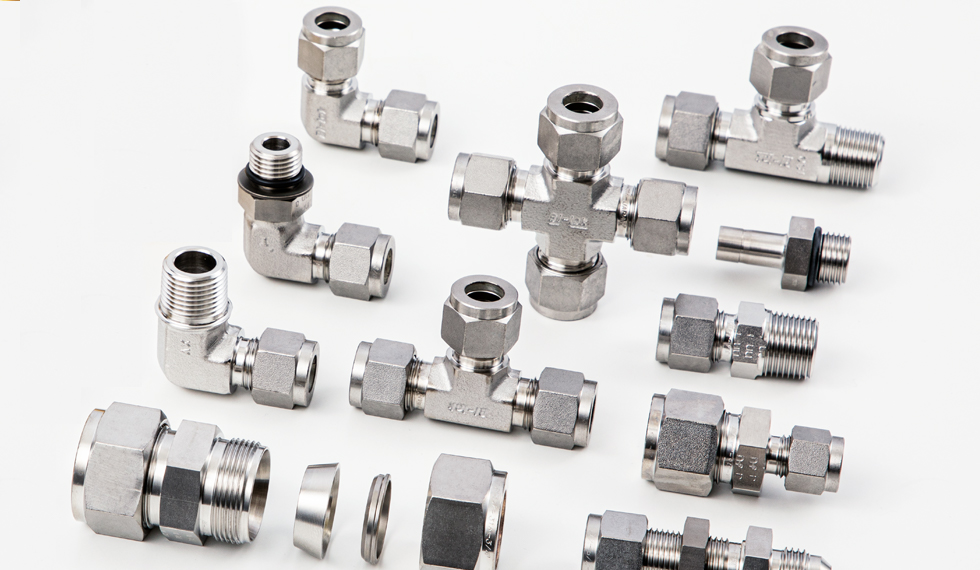

Double Ferrule Type Tube Fitting

Double Ferrule Type Tube FittingMechanical fittings with two ferrules

By simply tightening the nut, the back ferrule holds the tube and the front ferrule seals the fluid. Wetted parts are all made up of the same material, which means various fluids over a wide temperature range can be firmly sealed.

*Stainless products are RoHS compliant.- Catalog: BI-Lok

- Dimensions Table: Inch series

- Dimensions Table: Metric series

- Dimensions Table: Schedule Pipe series

BI-LOK (Metric)

BI-LOK (Pipe)

-

I-fitSingle-ferrule Fitting

I-fitSingle-ferrule FittingA two-part product : nut and body (the ferrule is integrated into the nut).

Dropping/losing ferrules, mixing up the ferrule orientation: these assembly worries are eliminated. You can choose between two types: the Rotation Control Type and the Nut Full Tightening Type (optional specification). The same fitting body is shared with the “Bi-Lok: Double-Ferrule Fitting”.

-

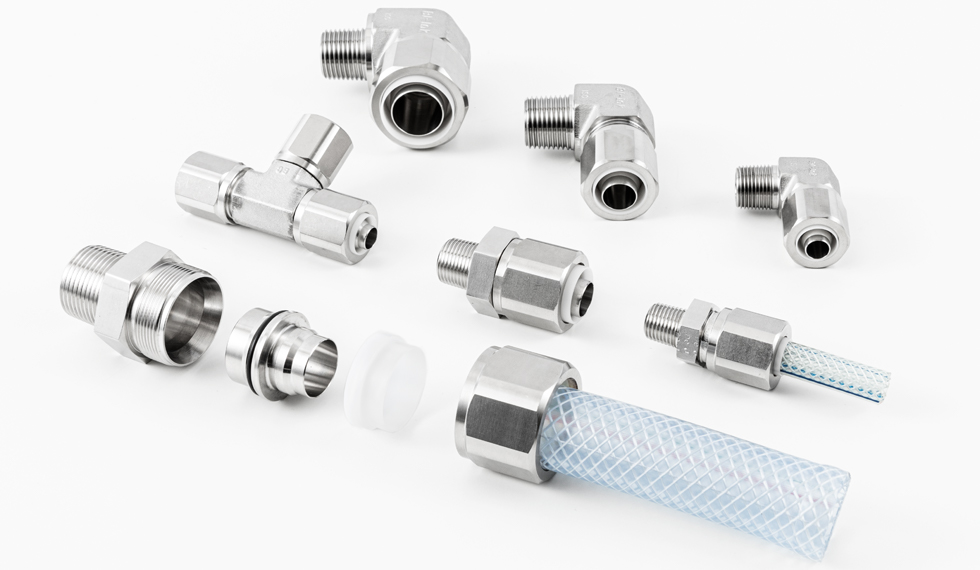

Fitting for Plastic Tubes

Fitting for Plastic TubesFitting developed for connecting plastic tubes

Since it has only two components (main body and the nut) and can be tightened by turning the nut fully, anyone can ensure “easy and secure” connection of plastic tubes.

EP-FIT (Inch)

EP-FIT (Metric)

-

Fitting for Vinyl Hoses

Fitting for Vinyl HosesFitting developed for soft vinyl chloride hoses

With a structure in which the hose inserted into the insert is pushed down by the sleeve through nut rotation, it enhances reliability against water leakage and hose pull-out.

e1 Touch (Metric) -

Weld-less Fitting

Weld-less FittingGood Design Award-winning product

Mechanical fitting for pipe size, designed to minimize the resistance of flow path.

E-FIT (Pipe) -

Automatic Welding Fitting

Automatic Welding FittingFitting, corresponding to automatic welding machines, used for high-purity gas systems of SC/LC manufacturing equipment

This product is made of exclusively high grade stainless steel and vacuum double packed in a clean room.

AWF (Inch)

*RoHS-compliant product -

Metal Gasket Seal FittingO-ring Seal Fitting

Metal Gasket Seal FittingO-ring Seal FittingFitting with a surface seal type metal gasket used for high-purity gas systems,enabling leak-free connection from vacuum to high pressure

Welding parts are made of exclusively high grade stainless steel and double vacuum packed in a clean room.

VTF (Inch)

*RoHS-compliant product

VTF-O (Inch) -

Metal Gasket Seal FittingClamp type

Metal Gasket Seal FittingClamp typeNew product replacing the conventional VTF fitting for high-purity gas for semiconductors

Twisting during piping work and particles generation during thread tightening, which were conventional problems of this type of fitting, are solved by applying a clamping method.

*RoHS-compliant product -

Quick Joint

Quick JointStainless one-touch connecting joint enabling quick and easy connection/detachment of piping

In addition to thread connection, fittings such as BI-Lok and EP-Fit are available.

QA (Inch)

QA (Metric) -

FF Quick JointsFull-flow quick fitting

FF Quick JointsFull-flow quick fittingA quickly-attachable-and-detachable fitting developed to realize energy-conservation goals.

While retaining the advantages of ‘simplicity and ease of removal,’ this fitting maximizes channel diameter (full flow) and pressure-loss reduction to conserve energy. Equipped with a foolproof mechanism (cannot be dismantled when handle is ‘open,’ and when dismantled, the handle cannot ‘open’,) incorrect operation is prevented.

- NEW

Catalog:QF

- NEW

-

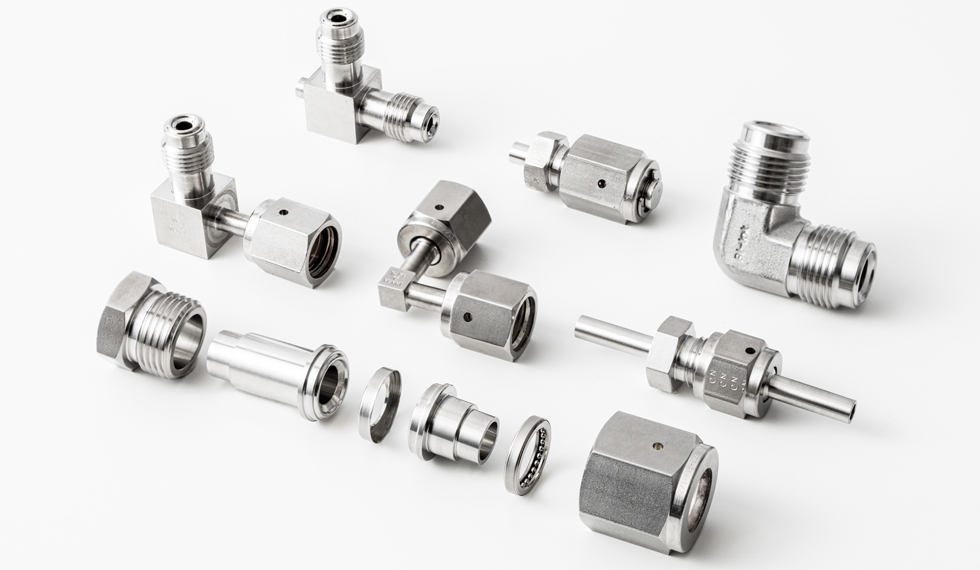

Bite Type Tube Fitting

Bite Type Tube FittingWeld-less high-pressure fitting for hydraulic application

This fitting eliminates the need for threading, welding, flaring, or brazing, and supports tube bending.

B (Metric)

B-1 (Metric)

CE (Metric)

NE (Metric)

KZC (Other)

KZL (Other)

KZU (Other)

VO (Manual)

VT (Manual)

-

ISO-compliant Bite Type Tube Fitting

ISO-compliant Bite Type Tube FittingBite type tube fitting conforming to ISO standards. Widely used in hydraulic piping systems of the machine tools market

Tightening can be completed by turning the nut fully, which eliminates variation in tightening operation and enables easy and secure piping work.

E-FITF (Metric) -

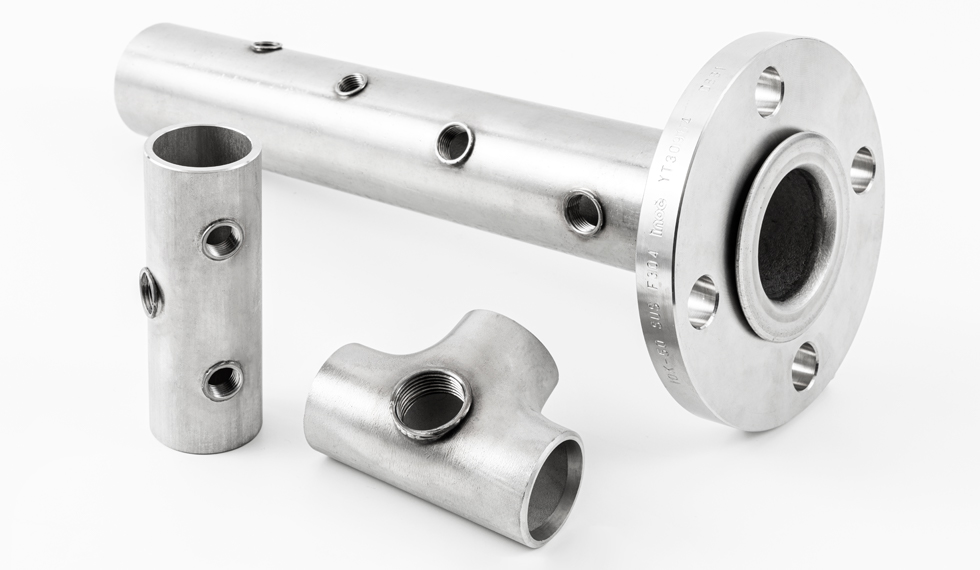

On-Site FlangeWeld-less Flange

On-Site FlangeWeld-less FlangeWith the On-Site Flange, you can manage your piping without welding.

Using a specialized tightening device, you can easily and reliably build your piping without specialization in welding or other skills. With a structure wedging the product’s sleeves into the pipe, you achieve equivalent strength to welding. Pre-welding fire prevention and post-welding acid washing are unnecessary, equipment downtime is greatly lessened, and in case of trouble, repair work is also easy.

-

High-pressure ThreadedSocket-weld Fitting

High-pressure ThreadedSocket-weld FittingFitting used for medium to high pressure piping for hydraulic application

It supports schedule pipes.

FA (Pipe)

HIGH-PRESSURE-THREADED (Pipe) -

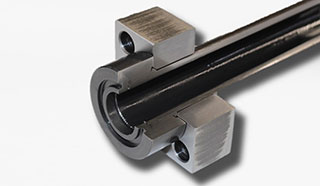

Swivel Joint

Swivel JointCompact and low-torque type swivel joint for hydraulic application

Effective as a measure against twisting of hydraulic hoses, it has increased its durability.

SJC (pipe)

SJH (pipe)

SJM (pipe)

SJS (pipe)

-

Hose Adapter

Hose AdapterThere is a lineup of various hose joints that can reduce pressure loss, noise, vibration, and contamination

Products that match user needs, including NNT series with smooth flow, are available.

NH (Pipe)

-

Bunki-kunBranch header piping

Bunki-kunBranch header pipingEnabling branch piping without joints

This branch piping fitting with a reduced flow resistance eliminates threading and welding processes. Directed corrugated shapes can also be manufactured.

-

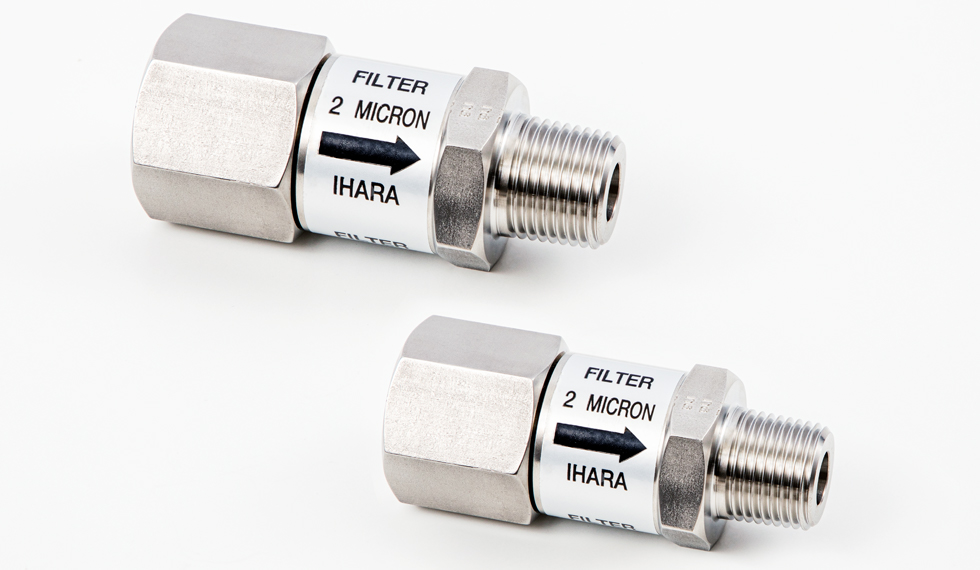

In-line Filter

In-line FilterFilter used for high-purity gas systems

Due to its replaceable element, maintenance is easy.

INF2 (Inch)